Below is a description of a tubular bagging machine and a corresponding sample order.

Technology Description

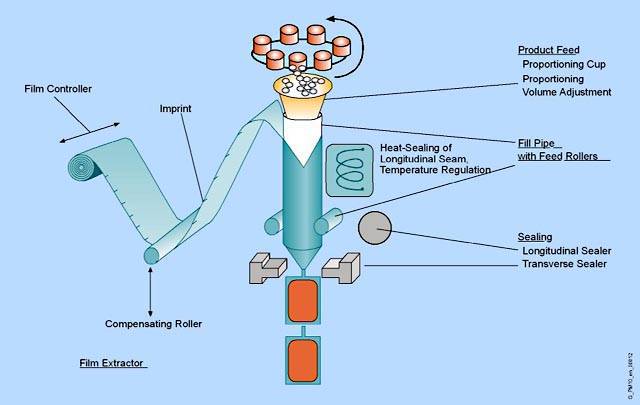

Film Extractor

The packaging film is unwound from the roll by the feed rollers on the fill pipe. The film first passes through a compensating roller. The limits of the compensating roller are measured. When the limits are reached, the machine is stopped immediately. The film controller positions the foil correctly.

Fill Pipe with Feed Rollers

The film is then pulled over the forming shoulder, creating a tube. This tube is then transported vertically through the machine via the fill pipe. The feed rollers take over the transport of the film.

When films with printed logos are used, the location of the imprint is continuously monitored. Any deviations, such as those caused by stretching of the foil, are corrected by the film feed so that the printed logo appears on the package within the required tolerance limits.

Sealing

The tubes are sealed longitudinally using heat and pressure; it is important to maintain constant sealing times.

Because this is a continuous tubular bagging machine, the transverse sealing bars follow a curve profile (similar to a D form).

Transverse sealing is also accomplished using temperature and pressure. The transverse sealing mechanism is driven by a servo motor and follows a cyclic motion.

Product Feed

When the tube is sealed by the transverse sealing mechanism, the bag is filled with product by means of a scale, a proportioning screw feeder, or, as in this example, a proportioning cup. At the same time, the bottom of the tube is sealed and the previously filled bag is separated.

The packages are then fed to other machines, such as collating packers.

General Machine Control

All relevant machine parameters can be changed during operation or when the machine is at standstill:

- Sealing temperature

- Switching times for product feed

- Bag length

- Film controller

Visual Display

The HMI performs the following functions:

- Operator control and monitoring

- Program storage and recipe management

A touch screen panel is required.

The longitudinal and transverse sealing applications mentioned above are available as standard applications for further adaptation. Please contact your local Siemens partner.

Tubular Bagging Machine Concept

The following table was derived from the application description to show how to set up solutions for implementing major machine functions.

Note:

A single task can be solved in any number of ways.

One possible solution is shown here. For simplification, a detailed selection of drive systems and connection methods has not been included.

Please refer to the configuration information in the appropriate catalogs.

All components are capable of communicating via PROFIBUS DP.

|

Subsystem

|

Functions/Requirements

|

Solution

|

Order no.

|

|

General machine control

|

Automation and motion control functions

|

|

|

| |

- Automation system is required that performs machine and sequence control as well as motion control

- Integrated in control cabinet

|

-

1 SIMOTION C230‑2

motion controller

|

6AU1 230-2AA00-0AA0

|

| |

- Storage of operating data and user program

|

-

SIMOTION Micro memory card

|

6AU1 700-0AA00-0AA0

|

| |

- 40 digital inputs for machine

|

-

1 SM 321

digital input module, 32 DI

(18 onboard DI, 22 DI on SM 321)

|

6ES7 321-1BL00-0AA0

|

| |

- 28 digital outputs for machine

|

-

1 SM 322

digital output module, 32 DO

(8 onboard DO, 20 DO from SM 322)

|

6ES7 322-1BL00-0AA0

|

| |

- 2 analog inputs for temperature control of longitudinal and transverse axis sealing

|

1 SM 331

analog input module, 2 AI

- Temperature feedback for temperature control

- Pressure is controlled externally (not via an analog input)

|

6ES7 331-7KB02-0AB0

|

| |

|

-

2 front connectors, 40‑pin, screw‑type terminal

- 1 x for SM 321 and 1 x for SM 322

|

6ES7 392-1AM00-0AA0

|

| |

|

-

1 front connector, 20‑pin, screw‑type terminal

|

6ES7 392-1AJ00-0AA0

|

| |

- Position-dependent digital output signals are required for controlling the switching states of longitudinal and transverse sealing

|

-

1 Motion Control Basic

technology package

enables the generation of output signals on the basis of a defined position

|

No license required

|

|

Film extractor

|

Film controller

- Positioning drive is required to set the correct position of the film

|

-

1 intelligent SIMODRIVE POSMO A positioning motor

|

6SN2 132-0AA11-1BA0

|

|

Fill pipe with feed rollers

|

Feed rollers

- Feed rollers, which are driven by a servo motor, draw the film over the fill pipe.

- Any deviations, such as those caused by stretching of the film, must be corrected by adjusting the film feed.

|

-

1 1FT/1FK servo motor

-

1 SIMODRIVE 611 universal converter system

The use of a servo drive enables accurate, quick-response motion of the film, ensuring the correct positioning of the printed logo.

|

See: Catalog DA 65.4;

In North America, see SIMODRIVE 611 universal and POSMO Catalog, Part 3, and High Performance Motors and Accessories Catalog, Part 2

|

|

Subsystem

|

Functions/Requirements

|

Solution

|

Order no.

|

|

Sealing

|

Longitudinal sealing

|

|

|

| |

- Motion for longitudinal sealing is generated by a drive, which ensures precise, quick-response performance.

|

-

1 1FT/1FK servo motor

-

1 SIMODRIVE 611 universal

converter system

The use of a servo drive ensures precise, quick-response performance.

|

See: Catalog DA 65.4;

In North America, see SIMODRIVE 611 universal and POSMO Catalog, Part 3, and High Performance Motors and Accessories Catalog, Part 2

|

| |

- Constant sealing times are required for uniform film sealing. If the sealing time is constant and the bag length profile is variable, the bag sealing motion is the variable factor. This means that different motion curve profiles have to be defined.

|

-

1 Cam Axis License technology package

The Cam software package can be used to generate cams, which establish a relationship between two axes (axes synchronization). In this case, the longitudinal sealing mechanism motion is defined in relation to the position of the bag (for example, 2 cm at 120 °, 7 cm at 270 °, etc.).

|

6AU1 820-1AC20-0AB0

License required

|

| |

Transverse sealing

- Transverse sealing motion is generated by a drive, which ensures precise, quick-response performance.

|

-

1 1FT/1FK servo motor

-

1 SIMODRIVE 611 universal converter system

The use of a servo drive ensures precise, quick- response performance.

|

See: Catalog DA 65.4;

In North America, see SIMODRIVE 611 universal and POSMO Catalog, Part 3, and High Performance Motors and Accessories Catalog, Part 2

|

| |

- In this "continuous operation", the machine does not stop to seal the bag. This means that the sealing mechanism must be synchronized with the bag motion. In order for the sealing function to operate correctly, the sealing motion must follow a profile.

|

-

1 Cam Axis License technology package

The Cam software package can be used to generate cams, which establish a relationship between two axes (axes synchronization). In this case, a "D" profile is defined for the transverse sealing motion in relation to the position of the bag (for example, 1 cm at 120 °, 3 cm at 270 °, etc.).

|

6AU1 820-1AC20-0AB0

License required

|

| |

- Controlling the line speed:

All axis motions must be coordinated

(synchronization). The bag position serves as the primary position reference.

|

-

Virtual axis

The software package can be used to generate a virtual leading axis.

The virtual leading axis is used to control the line speed. The leading axis also generates positioning values, which serve as the primary position reference. All axes can be synchronized with this primary position reference.

|

No license required

|

|

Product feed

|

Proportioning cup feed

- The product feed requires precise, quick-response performance of the drive system.

|

-

1 1FT/1FK servo motor

-

1 SIMODRIVE 611 universal converter system

The use of a servo drive ensures precise, quick-response performance of the product feed.

|

See: Catalog DA 65.4;

In North America, see SIMODRIVE 611 universal and POSMO Catalog, Part 3, and High Performance Motors and Accessories Catalog, Part 2

|

| |

- The product feed rate is based on the motion of the bag to be filled. In this continuous operation, the individual bags cannot be filled uniformly unless the feed rate is controlled. Therefore, the product feed rate is directly proportional to (synchronized with) the actual bag position.

|

-

1 Cam axis license

technology package

The Cam software package can be used to generate cams, which establish a relationship between two axes (axes synchronization). In this case, the product feed rate is defined in relation to the bag position/feed roller angle (for example, 12 cm3 at 120 °, 1,5 cm3 at 270 °, etc.). This ensures that each individual bag is filled to the same level.

|

6AU1 820-1AC20-0AB0

License required

|

| |

Proportioning volume control

- Positioning motor is required for final precise volume control (product filling)

|

-

1 intelligent SIMODRIVE POSMO A positioning motor

|

6SN2 132-0AA11-1BA0

|

|

Visual Display (HMI)

|

User interface

|

|

|

| |

- Operator control and monitoring via touch screen panel

- Selection of bag sizes and recipes

- Editing of user parameters

- Status display/diagnostics

|

SIMATIC TP 170B

- Touch screen panel

- STN color display

- Recipe management and program storage

|

6AV6 545-0BC15-2AX0

|

|