|

|

The ULTRAMAT 6 single-channel or dual-channel gas analyzers operate according to the NDIR two-beam alternating light principle and measure gases highly selectively whose absorption bands lie in the infrared wavelength range from 2 to 9 μm, such as CO, CO2, NO, SO2, NH3, H2O as well as CH4 and other hydrocarbons.

Single-channel analyzers measure up to 2 gas components, dual-channel analyzers up to 4 gas components simultaneously.

ULTRAMAT 6, 19“ unit and field unit |

Особенности

- High selectivity with double-layer detector and optical coupler

- Reliable measurements even in complex gas mixtures

- Low detection limits

- Measurements with low concentrations

- Corrosion-resistant materials in gas path (option)

- Measurement possible in highly corrosive sample gases

- Cleanable sample cells

- Cost saving in further use in case of pollution

- Electronics and physics: gas-tight isolation, purging is possible, IP65

- High service life even in harsh environments

- Heated versions (option)

- Use also in presence of gases condensing at low temperature

- EEx(p) for zones 1 and 2 (according to ATEX 2G and ATEX 3G).

|

Область примененияApplication

- Measurements for boiler control in combustion plants

- Emission measurements in incineration plants

- Measurements in the automotive industry (test benches)

- Warning equipment

- Process gas concentrations in chemical plants

- Trace measurements in pure gas processes

- Environment protection

- MAC-value monitoring at place of work

- Quality monitoring

- Ex versions to analyze flammable and non-flammable gases or vapors for use in hazardous areas.

Special versions

- Special applications

Besides the standard combinations special applications concerning material of the gas path, material of the sample cells (e.g. titanium, Hastelloy C22) and sample components are also available on request.

- TÜV version

TÜV-approved versions are available for measurement of CO, NO and SO2 according to 13. BImSchV and TA Luft.

Smallest TÜV-approved and permitted measuring ranges:

- 1-component analyzer

CO: 0 to 50 mg/m3

NO: 0 to 100 mg/m3

SO2: 0 to 75 mg/m3 - 2-component analyzer (series connection)

CO: 0 to 75 mg/m3

NO: 0 to 200 mg/m3

Furthermore, the TÜV-approved versions of the ULTRAMAT 6 comply with the requirements of EN 14956 and of QAL 1 according to EN 14181. Conformity of the analyzers with both standards is TÜV-certified.

Determination of the analyzer drift according to EN 14181 (QAL 3) can be carried out manually or also with a PC using the SIPROM GA maintenance and servicing software. In addition, selected manufacturers of emission evaluation computers offer the possibility for downloading the drift data via the analyzer’s serial interface and to automatically record and process them in the evaluation computer.

|

Дизайн19“ unit

- With 4 HU for installation

- in swing frame

- in cabinets, with or without slide rails

- Front panel for service can be hinged down (laptop connection)

- Internal gas paths: flexible tube made of FKM (Viton) or pipe made of titanium or stainless steel

- Gas connections for sample gas input and output: pipe diameter 6 mm or 1/4"

- Flowmeter for sample gas on the front panel (option).

Field unit

- Two-door housing with gas-tight separation of analyzer and electronics sections from gas path

- Each half of the enclosure can be purged separately

- Analyzer section and piping can be heated up to 65 °C (option)

- Gas path: hose made of FKM (Viton) or pipe made of titanium or stainless steel (further materials possible as special applications)

- Gas connections for sample gas inlet and outlet: pipe union for pipe diameter 6 mm or 1/4"

- Purging gas connections: pipe diameter 10 mm or 3/8".

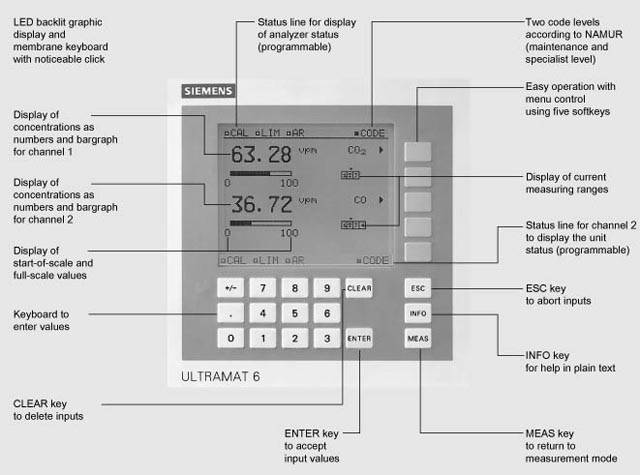

Display and control panel

- Large LCD panel for simultaneous display of:

- Measured value (digital and analog displays)

- Status line

- Measuring ranges

- Contrast of LCD panel adjustable using menu

- Washable membrane keyboard with five softkeys

- Menu-based operation for parametrization, test functions, calibration

- User help in plain text

- Graphic display of concentration trend; programmable time intervals

- Operation software in two languages:

German/English, English/Spanish, French/English, Italian/English.

Inputs and outputs

- One analog output per sample component

- Two analog inputs freely configurable (e.g. correction of cross interferences or external pressure sensor)

- Six binary inputs freely configurable (e.g. for range switching, processing external signals from sample conditioning)

- Six relay outputs freely configurable (e.g. failure, maintenance request, limit alarm, external solenoid valves)

- Extension with eight additional binary inputs and eight additional relay outputs, e.g. for automatic calibration with up to four calibration gases.

Communication

- RS 485 present in basic unit (connection at the rear; with 19“ unit also possibility of connection behind the front plate).

Options

- AK interface for the automotive industry with extended functions

- RS 485/RS 232 converter

- RS 485/Ethernet converter

- Linking to networks via PROFIBUS DP/PA interface

- SIPROM GA software as service and maintenance tool.

ULTRAMAT 6, membrane keyboard and graphic display

Versions – Wetted parts, standard

|

Gas path

|

19“ unit

|

Field unit

|

Ex field unit

|

|

With hoses

|

Bushing

|

SS, type No. 1.4571

|

-

|

|

Hose

|

FKM (z. B. Viton)

|

|

Sample cell:

|

|

|

|

Aluminum

|

|

|

Aluminum

|

|

|

SS, type No. 1.4571,

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

|

|

CaF2, adhesive: E353,

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

|

With pipes

|

Bushing

|

Titanium

|

|

Pipe

|

Titanium,

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

|

Sample cell:

|

|

|

|

Aluminum

|

|

|

Tantalum (only for sample cell length 20 to 180 mm)

|

|

|

CaF2, adhesive: E353,

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

|

With pipes

|

Bushing

|

SS, type No. 1.4571

|

|

Pipe

|

SS, type No. 1.4571,

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

|

Sample cell:

|

|

|

|

Aluminum

|

|

|

Aluminum or tantalum (Ta: only for sample cell length 20 to 180 mm)

|

|

|

CaF2, adhesive: E353,

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

Options

|

Options

|

19“ unit

|

Field unit

|

Ex field unit

|

|

Flowmeter

|

Metering pipe

Float

Float limit

Elbows

|

Duran glass

Duran glass

PTFE (e.g. Teflon)

FKM (e.g. Viton)

|

-

|

-

|

|

Pressure switch

|

Membrane

Enclosure

|

FKM (e.g. Viton)

PA 6.3 T

|

-

|

-

|

Versions – Wetted parts, special applications (examples)

|

Gas path

|

19“ unit

|

Field unit

|

Ex field unit

|

|

With pipes

|

Bushing

|

e.g. Hastelloy C22

|

|

Pipe

|

e.g. Hastelloy C22,

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

|

Sample cell:

|

|

|

|

e.g. Hastelloy C22

|

|

|

CaF2, without adhesive

O-ring: FKM (e.g. Viton) or FFKM (Kalrez)

|

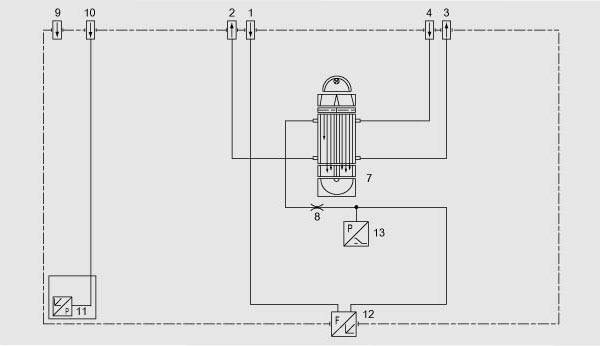

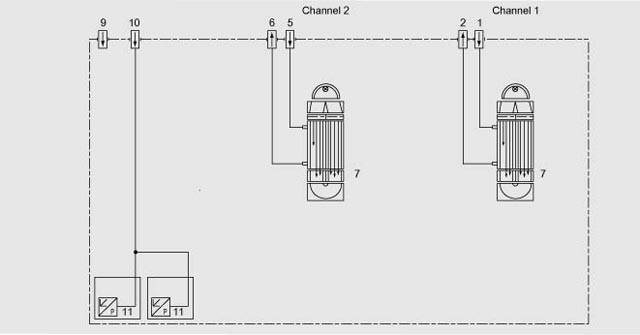

Gas path (19“ unit)

|

Key to gas path figures

|

|

1

|

Sample gas inlet channel 1

|

8

|

Restriction

|

|

2

|

Sample gas outlet channel 1

|

9

|

Purging gas inlet

|

|

3

|

Reference gas outlet (option)

|

10

|

Gas inlet atmospheric pressure sensor

|

|

4

|

Reference gas inlet (option)

|

11

|

Atmospheric pressure sensor

|

|

5

|

Sample gas inlet channel 2

|

12

|

Flowmeter in sample gas path (option)

|

|

6

|

Sample gas outlet channel 2

|

13

|

Pressure switch in sample gas path (option)

|

|

7

|

IR bench

|

|

|

Gas path ULTRAMAT 6, single-channel unit, 19“ unit, with flow-type reference cell (option)

Gas path ULTRAMAT 6, dual-channel unit, 19“ unit

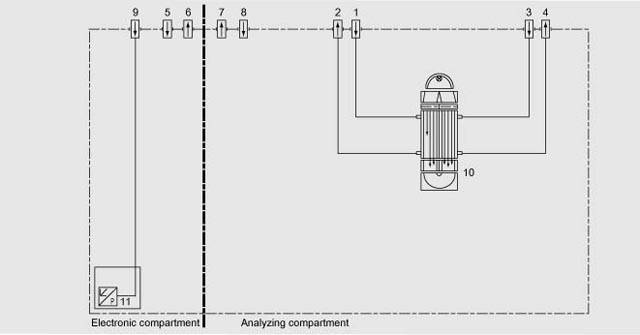

Gas path (field unit)

|

Key to gas path figures

|

|

1

|

Sample gas inlet

|

7

|

Purging gas outlet (anlyzing side)

|

|

2

|

Sample gas outlet

|

8

|

Purging gas inlet (anlyzing side)

|

|

3

|

Reference gas inlet (option)

|

9

|

Gas inlet atmospheric pressure sensor

|

|

4

|

Reference gas outlet (option)

|

10

|

IR bench

|

|

5

|

Purging gas inlet (electronic side)

|

11

|

Atmospheric pressure sensor

|

|

6

|

Purging gas outlet (electronic side)

|

|

|

Gas path ULTRAMAT 6, field unit, with flow-type reference cell (option)

|

ФункцииMode of operation

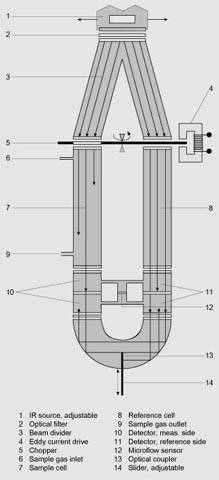

The ULTRAMAT 6 gas analyzer operates according to the infrared two-beam alternating light principle with double-layer detector and optical coupler.

The measuring principle is based on the molecule-specific absorption of bands of infrared radiation. The absorbed wavelengths are characteristic to the individual gases, but may partially overlap. This results in cross-sensitivities which are reduced to a minimum in the ULTRAMAT 6 gas analyzers by the following measures:

- Gas-filled filter cell (beam divider)

- Double-layer detector with optical coupler

- Optical filters if necessary.

The figure shows the measuring principle. An IR source (1) which is heated to approx. 700 ºC and which can be shifted to balance the system is divided by the beam divider (3) into two equal beams (sample and reference beams). The beam divider also acts as a filter cell.

The reference beam passes through a reference cell (8) filled with N2 (a non-infrared-active gas) and reaches the right-hand side of the detector (11) practically unattenuated. The sample beam passes through the sample cell (7) through which the sample gas flows and reaches the left-hand side of the detector (10) attenuated to a lesser or greater extent depending on the concentration of the sample gas. The detector is filled with a defined concentration of the gas component to be measured.

The detector is designed as a double-layer detector. The center of the absorption band is preferentially absorbed in the upper detector layer, the edges of the band are absorbed to approximately the same extent in the upper and lower layers. The upper and lower detector layers are connected together via the microflow sensor (12). This coupling means that the spectral sensitivity has a very narrow band.

The optical coupler (13) lengthens the lower receiver cell layer optically. The infrared absorption in the second detector layer is varied by changing the slider position (14). It is thus possible to individually minimize the influence of interfering components.

A chopper (5) rotates between the beam divider and the sample cell and interrupts the two beams alternately and periodically. If absorption takes place in the sample cell, a pulsating flow is generated between the two detector levels which is converted by the microflow sensor (12) into an electric signal.

The microflow sensor consists of two nickel grids heated to approx. 120 °C which, together with two further resistors, form a Wheatstone bridge. The pulsating flow together with the very close arrangement of the Ni grids leads to a change in resistance. This leads to an offset in the bridge which is dependent on the concentration of the sample gas.

Notes

The sample gases have to enter the analyzer dustfree. Avoid condensate in the sample cells. Therefore an appropriate gas preparation is required in most applications.

The ambient air of the analyzer should be, in a large extent, free of high concentration of the component to be measured.

Flow-type reference sides with reduced flow must not be used with flammable or toxic gases.

Channels with electronically suppressed zero only differ from the standard version by the measuring ranges parameterization.

Physically suppressed zeros are implemented as special applications.

ULTRAMAT 6, mode of operation

Essential characteristics

- Four freely-programmable measuring ranges per component

- Measuring ranges with suppressed zero possible

- Measuring range identification

- One electrically isolated signal output 0/2/4 to 20 mA per component

- Autoranging or manual range switching possible; remote switching is also possible

- Differential measuring ranges with flow-type reference cell

- Storage of measured values possible during calibration

- Time constants selectable within wide limits (static/dynamic noise suppression); i.e. the response time of the analyzer or the component can be matched to the respective application

- Fast response time

- Low long-term drift

- Measuring-point selection for up to 6 measuring points (programmable)

- Measuring point identification

- Monitoring of sample gas flow (option)

- Internal pressure sensor for correction of variations in atmospheric pressure in the range 600 to 1200 hPa absolute

- External pressure sensor can be connected for correction of variations in the process gas pressure in the range 600 to 1500 hPa absolute (option)

- Two-stage access code to prevent unintentional and unauthorized inputs

- Automatic range calibration can be parameterized

- Simple handling using menu-based operation with numerical membrane keyboard

- Operation based on NAMUR Recommendation

- Customer-specific analyzer versions such as e.g.:

- Customer acceptance

- Tag labels

- Drift recording

- Simple analyzer exchange since electric connections are easy to remove

- Sample cell for use in presence of highly corrosive sample gases (e.g. tantalum layer or Hastelloy C22).

Additional characteristics, dual-channel version

- Separate design of physical unit, electronics, inputs/outputs and power supply for each channel

- Display and operation via common LCD panel and keyboard

- Channels 1 and 2 can be converted to connection in series (linking of gas connections from channel 1 to channel 2 on rear).

| |

|

|