ФункцииMode of operation

The measuring principle is based on the different thermal conductivity of gases.

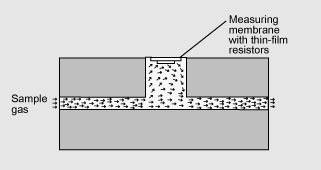

The CALOMAT 6 sensor is a micromechanical-made Si chip with a measuring membrane and thin-film resistors.

The resistors are adjusted on a constant temperature. This requires an current intensity depending on the sample gas thermal conductivity. Further this „coarse value“ is electronically processed and used to calculate the gas concentration.

The sensor is located in a thermostatically-controlled stainless steel enclosure in order to prevent influences of ambient temperature changes.

To prevent the influences by the sample gas flow changes, the sensor is not placed in the main flow.

Note

The sample gas needs to be free of dust. Condensate (dew point of sample gas < ambient temperature) in the cells must be avoided. That is why the most measuring tasks require an appropriate gas preparation.

CALOMAT 6, mode of operation

Special characteristics

- Four freely-progammable measuring ranges, also with zero offset, all measuring ranges linear

- Smallest spans up to 1% H2 (with suppressed zero: 95 to 100% H2) possible

- Electrically isolated analog output 0/2/4 to 20 mA (also inverted)

- Autoranging or manual range switching possible; remote switching is also possible

- Storage of measured values possible during calibration

- Time constants selectable within wide limits (static/dynamic noise suppression); i.e. the response time oft he analyzer can be matched to the respective application

- Short response time

- Low long-term drift

- Measuring point selection for up to 6 measuring points (can be parameterized)

- Measuring range identification

- Measuring point identification

- External pressure sensor for correction of pressure variations in sample gas

- Automatic range calibration can be parameterized

- Operation based on NAMUR Recommendation

- Two operation levels with separate access code to prevent unintentional and unauthorized inputs

- Simple handling using a numerical membrane keypad including operator prompting

- Customer-specific analyzer options such as e.g.:

- Customer acceptance

- Tag labels

- Drift recording

- Clean for O2-Service.

Spans

The smallest and largest spans which are possible depend on the measured component (type of gas) as well as the respective application.

The smallest possible spans listed below refer to N2 as the residual gas. With other gases which have a larger/smaller thermal conductivity than N2, the smallest possible span is also larger/smaller.

|

Component

|

Smallest possible span

|

|

H2

|

0 ... 1% (95 ... 100%)

|

|

He

|

0 ... 2%

|

|

Ar

|

0 ... 10%

|

|

CO2

|

0 ... 20%

|

|

CH4

|

0 ... 15%

|

|

H2 in blast furnace gas

|

0 ... 10%

|

|

H2 in converter gas

|

0 ... 20%

|

|

H2 with wood gasification

|

0 ... 30%

|

Influence of interfering gases

Knowledge of the sample gas composition is necessary to determine the influence of residual gases with several interfering components.

The following table lists the zero offsets expressed in % H2 resulting from 10% residual gas (interfering gas) in each case.

|

Component

|

Zero offset

|

|

Ar

|

-1.28%

|

|

CH4

|

+1.59%

|

|

C2H6 (non-linear response)

|

-0.04%

|

|

C3H8

|

-0.80%

|

|

CO

|

-0.11%

|

|

CO2

|

-1.07%

|

|

He

|

+6.51%

|

|

H2O (non-linear response)

|

+1.58%

|

|

NH3 (non-linear response)

|

+1.3%

|

|

O2

|

-0.18%

|

|

SF6

|

-2.47%

|

|

SO2

|

-1.34%

|

|

Air (dry)

|

+0.5%

|

For residual gas concentrations differing from 10%, the correspondant multiple of the table value gives an acceptable approximation. This is valid for for residual gas concentrations up to 25% (dependent on gas type).

The thermal conductivity of most gas mixtures has a non-linear response. Even ambiguous results, such as e.g. with NH3/N2 mixtures, can occur within a specific concentration range.

In addition to a zero offset, it should also be noted that the gradient of the characteristic is influenced by the residual gas. However, this effect is negligible for most gases.

In case of correction of the influence of interfering gases with additional analyzers (ULTRAMAT 6/ULTRAMAT 23), the resulting measuring error can – depending on the application – amount up to 5% of the smallest measuring range of the application.

Example interfering gas correction

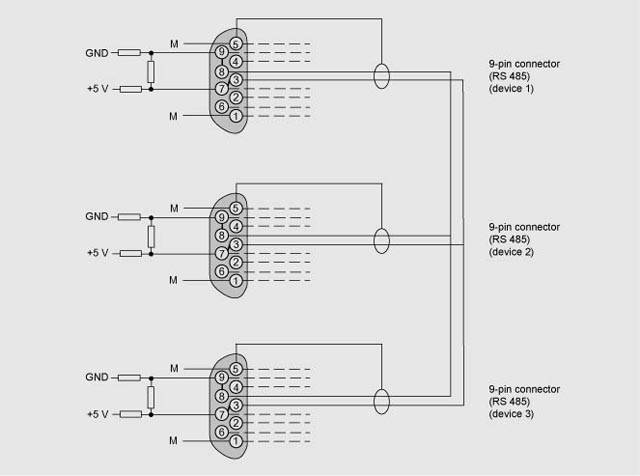

Specification of the interface cable

|

Characteristic impedance

|

100 ... 300 Ω, with a measuring frequency of > 100 kHz

|

|

Cable capacity

|

typ. < 60 pF/m

|

|

Wire section

|

> 0.22 mm2, corresp. AWG 23

|

|

Cable type

|

twisted pairs, 1 x 2 wire of cable section

|

|

Signal attenuation

|

max. 9 dB over the whole length

|

|

Screening

|

copper braid shield or braid shield and foil screen

|

|

Connection

|

pin 3 and pin 8

|

Bus terminating resistors

The pin 3-7 and 8-9 of the first and last connector of a bus cable have to be bridged (see figure).

Note

It is advisable to install a repeater on the device side in case of a cable length increasing 500 m or of high interferences.

Up to four components can be corrected via ELAN bus, a cross correction can be effected for up to two components via analog inlet.

Bus cable with connector assignments |