|

|

The FIDAMAT 6 gas analyzer is suitable for the determination of the total hydrocarbon content in the air and high-boiling gas mixtures.

FIDAMAT 6 |

ОсобенностиThe FIDAMAT 6 gas analyzer stands out for its wide range of applications

- where up to 100% H2O steam is present

- in high-purity gas applications

- with high-boiling components (up to 200 °C)

- where corrosive gases are present (with pre-filter).

The FIDAMAT 6 has:

- extremely low cross sensitivity to interference gases

- low combustion air consumption

- low oxygen influence on measured value.

The device is also equipped with warning and fault messages:

- in the event of combustion gas failure

- if the flame is extinguished

- to indicate faults in the pump and filter.

|

Область примененияApplication areas

- Environmental protection

- Wastewater (in conjunction with a stripping device, verification of the hydrocarbon content of liquids)

- Measurement of flue gases in accordance with German emission protection legislation and air purity guidelines for fuel types oil, coal, gas, and waste (with German Technical Inspectorate approval)

- MAC value monitoring at places of work

- Quality monitoring

- Process exhaust monitoring

- High-purity gas measurement in media such as O2, CO2, inert gases and cold sample gases

- Measurement of corrosive and condensing gases

- Process optimization.

Further applications

- Chemical plants

- Gas manufacturers (high-purity gas monitoring)

- Research and development

- Cement industry (measurement of emissions)

- Paint shops and dry-cleaning systems

- Refineries (tank storage, waste water)

- Drying systems

- Solvent recovery systems

- Pharmaceuticals industry

- Automobile industry (engine development, engine and transmission development and certification).

Special applications

Special applications are available on request in addition to the standard combinations. |

Дизайн

- 19“ unit with 4 HU for installation

- in swing frame

- in cabinets, with or without slide rails

- Front panel for service can be hinged down (laptop connection)

- Gas connections for sample gas input and output as well as combustion gas and combustion air, pipe diameter 6 mm or 1/4"

- Gas and electrical connections at the rear

- Internal gas paths: stainless steel (SS, type No. 1.4571).

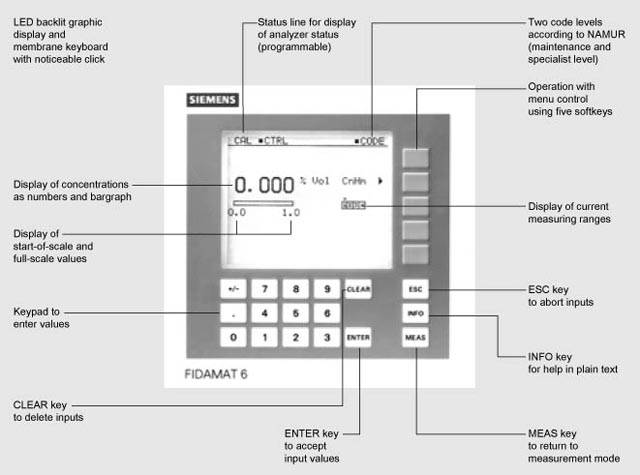

Display and control panel

- Large LCD panel for simultaneous display of:

- Measured value

- Status line

- Measuring ranges

- Contrast of LCD panel adjustable via menu

- Permanent LED backlighting

- Washable membrane keyboard with five softkeys

- Menu-based operation for configuration, test functions and

calibration

- User help in plain text

- Graphic display of concentration trend; programmable time

intervals.

Inputs and outputs

- One analog output

- Two programmable analog inputs

- Six binary inputs freely configurable (e.g. for range switching, processing of external signals from sample preparation)

- Six relay outputs freely configurable (failure, maintenance request, maintenance switch, limit alarm, external solenoid valves, measuring point switchover)

- Extension with eight additional binary inputs and eight additional relay outputs for automatic calibration with up to four calibration gases.

Communication

- RS 485 included in basic unit (connection at the rear).

Options

- RS 485/RS 232 converter

- RS 485/Ethernet converter

- Linking to networks via PROFIBUS DP/PA interface

- SIPROM GA software as service and maintenance tool.

FIDAMAT 6, membrane keyboard and graphic display

Executions of the wetted parts

|

Gas path

|

Material

|

|

Tubing

|

SS, type No. 1.4571

|

|

Gas inlet

|

SS, type No. 1.4571

|

|

Gaskets

|

Graphite

|

|

Sample gas restrictor

|

Quartz

|

|

Auxiliairy gas restrictors

|

SS, type No. 1.4571

|

|

Pump membrane

|

PTFE

|

|

Pump head

|

SS, type No. 1.4571

|

|

Detector

|

|

|

Nozzle

|

Quartz

|

|

FID housing

|

SS, type No. 1.4571

|

Gas path

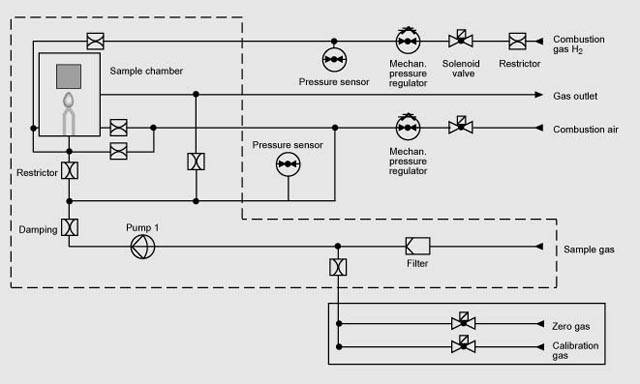

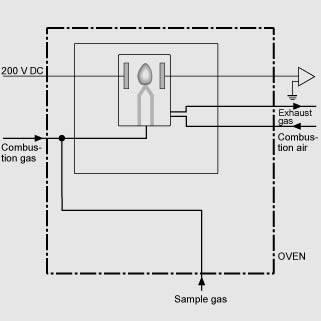

FIDAMAT 6 gas analyzer for determining the total hydrocarbon content, gas path with pump to connect combustion air

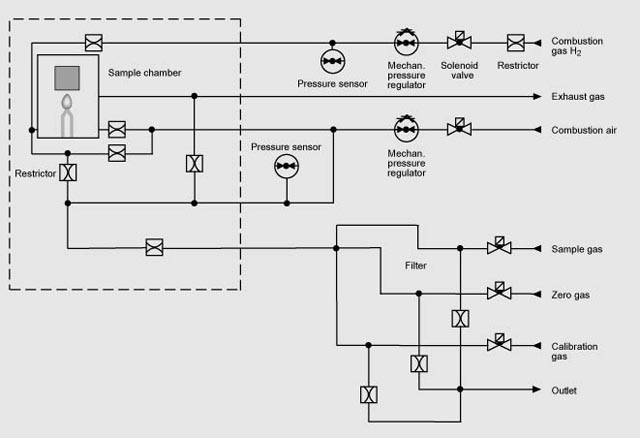

FIDAMAT 6 gas analyzer for determining the total hydrocarbon content, gas path without pump to connect combustion air

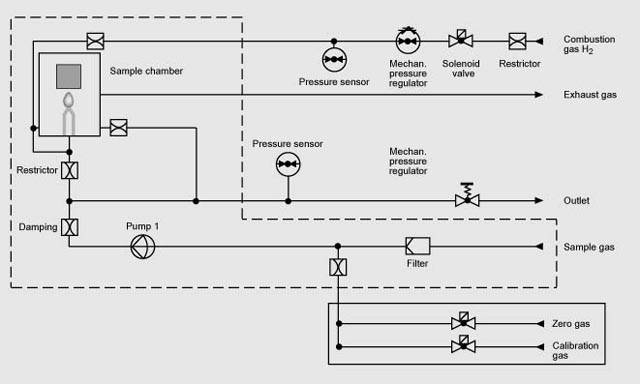

FIDAMAT 6 gas analyzer for determining the total hydrocarbon content, gas path without pump to connect combustion air |

ФункцииMode of operation

The FIDAMAT 6 performs substance-specific measurement and not component-specific measurement. It measures the total of all hydrocarbons in a sample gas, although with different weighting of the hydrocarbon molecules. At initial exposure, the display is proportional to the number of C atoms in the molecule in question. There are fluctuations in practice, however. The display deviation for the relevant molecule is expressed by the response factor.

The sample gas is supplied to the FIDAMAT 6 under overpressure or drawn in by the built-in diaphragm pump (optionally via a heated line and an additional filter) and passed into the flame ionization detector via an obstruction-proof fused-silica restrictor.

In the detector, the hydrocarbons in the sample gas are burned in a detonating gas flame. Burning partially ionizes the proportion of organically-bound hydrocarbons. The released ions are converted into a stream by the tension between two electrodes and measured using a highly sensitive amplifier. The current measured is proportional to the quantity of organically-bound C atoms in the sample gas.

A pressure regulator holds the combustion gas pressure constant. The balanced system of pump, capillary tubes, and combustion gas pressure regulators ensures that the sample gas pressure is kept constant.

When the analyzer is switched on, ignition and pump startup are automatic when the setpoint temperature has been reached.

FIDAMAT 6, mode of operation

The FIDAMAT 6 provides various messages in the form of floating contacts:

- Maintenance request

E.g. sample gas flow (filter/pump)

Fan failure (advance warning for measuring accuracy).

The measured value remains unaffected.

- Fault

E.g. hydrogen, combustion gas, and sample gas pressure, temperature, physical part and pump, fault in the electronics (temperature).

The measured value can be influenced.

- Failure

In the event of failure of, for example, the electronics, voltage supply, combustion gas, combustion air and sample gas, the device automatically shuts down (the combustion gas valve is closed).

Note

The sample gas needs to be free of dust. Condensate in the cells must be avoided. That is why the most measuring tasks require an appropriate gas preparation.

Essential characteristics

- Four freely-parameterizable measuring ranges, also with suppressed zero point, all measuring ranges linear

- Galvanically isolated measured value output 0/2/4 bis 20 mA (also inverted)

- Automatic measuring range switchover selectable, remote switchover also possible

- Storage of measured value during calibration possible

- Range identification

- Measuring-point selection for up to 6 measuring points

- Measuring point identification

- Time constants (static/dynamic noise suppression) can be selected within wide limits; this means the response time of the device can be adapted to the respective measuring task

- Simple handling thanks to menu operation

- Low long-term drift

- Two operation levels with separate authorization code to prevent unsupervised and unauthorized use

- Parameterizable automatic measuring range calibration

- Operation based on the NAMUR recommendation

- Customized device versions such as:

- Customer acceptance

- TAG labels

- Drift recording

- Wear-free, corrosion-proof filter housing

- No obstructions in the sample gas restrictors through the use of a quartz restrictor tube

- Purge function in the event of device failure and auxiliary power failure (avoids build-up of toxic and corrosive substances in the device)

- Low combustion air consumption

- Response factors comply with the minimum requirements in accordance with German air purity guidelines and the Working Group of the German Automobile Industry

- Simple operation with the help of a numeric membrane keyboard and operator prompting.

Response factors (examples, mean values)

|

Substance

|

Mean response factor

|

|

n-butane

|

1.00

|

|

n-propane

|

1.00

|

|

n-heptane

|

1.00

|

|

Cyclohexane

|

1.08

|

|

Isopropanol

|

0.81

|

|

Toluene

|

1.06

|

|

Acetone

|

0.94

|

|

Ethylacetate

|

0.77

|

|

Isobutyl acetate

|

0.83

|

|

Methane

|

1.06

|

|

Ethane

|

0.99

|

|

n-hexane

|

1.01

|

|

iso-octane

|

1.04

|

|

Ethine (acetylene)

|

0.91

|

|

Propene

|

0.84

|

|

Methanol

|

0.87

|

|

Ethanol

|

0.83

|

|

Ethanoic acid

|

1.13

|

|

Methyl acetate

|

0.67

|

|

Benzene

|

1.07

|

|

Ethylbenzene

|

0.96

|

|

p-xylene

|

1.03

|

|

Dichloromethane

|

1.13

|

|

Trichloroethylene

|

1.01

|

|

Tetrachlorethene

|

1.07

|

|

Chloroform

|

0.72

|

|

Chlorobenzene

|

1.15

|

Cross influences (examples) 1)

|

Interference component

|

Concentration of the interference component

|

Induced cross influence

|

|

O2 in N2

|

(21 Vol.%)

|

< 0.3 mg/m3

|

|

SO2 in N2

|

(258 mg/m3)

|

< 0.15 mg/m3

|

|

NO in N2

|

(310 mg/m3)

|

< 0.5 mg/m3

|

|

NO2 in synth. air

|

(146 mg/m3)

|

< 0.1 mg/m3

|

|

CO in N2

|

(461 mg/m3)

|

< 0.15 mg/m3

|

|

CO2 in N2

|

(18 Vol.%)

|

< 0.1 mg/m3

|

|

HCl in N2

|

(78 mg/m3)

|

< 0.3 mg/m3

|

1) With measuring range 0 … 15 mg/m3.

| |

|

|