ФункцииMotion Control Basic

The license for the use of the Motion Control Basic technology package is acquired with the SIMOTION unit.

The technology package is suitable for variable-speed drives.

Motion Control Basic Functions

Selection of speed setpoints

Speed setpoints can be selected from the program, for instance, to control a winder drive.

Cams

The following cams (PLS) can be implemented:

- Operating cams

- Path-path cams

- Path-time cams

- Dynamic cams, derivative action for activation/deactivation can be set separately

- Counting cams

- Triggered on rising/falling edge

The status of the cams (PLS) can be output to:

- Internal variables

- Digital outputs

The following can be assigned as the basis of reference for the cam (PLS) signal edges:

- Axis setpoints

- Axis actual values

- External encoders

Actual value recording with external encoder

The actual values of axis positions can be measured using external encoders.

Further information:

-

For technical specifications, see Section "Function Overview"

-

For ordering data, see "Runtime Software/General"

Position

The Position technology package requires a license and provides the following functions:

- Controlled positioning of individual axes:

Axes can be moved without interpolation. Possible settings include:

- Axis, position

- Speed

- Acceleration/delay, jerk

- Transient response to the next movement

- Motion profiles for axis defined by means of cams

- Path over time

- Speed over time

- Speed over path

- Force and pressure control of an axis

- Changeover from position to pressure controlled operation

- Force and pressure limitation of an axis

- Force and pressure profiles can be preset via cams

- For control and limitation

- Force/pressure over time

- Force /pressure over path

- Travel to endstop

- Stop when following error limit reached

- Stop when torque limit reached

- Stop with defined torque

- Travel with adjustable torque limitation

- Programmable motion control:

Motion programs can be assigned to the different execution levels, such as event-driven or time-controlled execution levels.

- Independent, overriding, and superimposed motion:

Successive motions can be:

- Independent (individual), meaning that the axis stops between motions (exact positioning)

- Overriding, meaning that the transition to the next motion begins the moment braking begins

- Another motion can be superimposed on an active motion, for example, superimposing of a positioning motion on a synchronous operation motion.

- Simultaneous start of positioning axes:

Positioning axes can be started simultaneously.

The following axis types are supported:

- Linear axis, rotary axis

- Virtual axis

- Homing:

The following types of homing are supported:

- Homing mark and encoder zero mark

- With homing mark only

- With encoder zero mark only

- Set homing point

- On-the-fly measurement:

This function is used to save the current actual value. It is triggered by a measuring input that controls the high-speed input. The actual value can be evaluated by means of the application program. This function enables even active motions to be modified directly, for example.

- Encoder switchover, 2nd encoder:

Up to two encoders can be assigned to a single axis:

- Only one encoder is active for position control.

- The switchover from one encoder to the other can take place "on-the-fly".

- The actual value of the inactive encoder can be read by means of the application program and used for specific monitoring purposes, for example.

Further information:

-

For technical specifications, see Section "Function Overview"

-

For ordering data, see "Runtime Software/General"

Gear

The Gear technology package requires a license and provides the following functions in addition to the functions provided by the Position technology package:

- Angular synchronization, electronic gearing:

This function enables implementation of angle-synchronous operation with long-term stability over several axes. The gear ratio can be set at very precise intervals.

- Leading axis: virtual/real axis or external encoder

The master value can change "on-the-fly" between the master value sources. The following can be used as leading axis or as master value source for the following axes:

- Virtual axis:

The virtual axis exists only in the controller, and thus has no real drive, motor, or encoder. Like a real axis, the virtual axis can be controlled by means of commands. The motion control system uses the interpolator to compute the setpoints, which can be used, for example, as master value for synchronous operation. - Real axis:

The real axis is a leading axis that is computed in the SIMOTION system. - External axis/encoder:

The actual value of the leading axis is acquired by means of an external encoder and, after conditioning, is made available as master value.

- Setpoint coupling and actual value coupling with compensation of delays

- Change of the master axis can take place "on-the-fly".

- The angular position and electronic gear ratio of the axes can also be modified during operation.

- External synchronization:

Material slip can be corrected using on-the-fly measurement and a superimposed positioning function, for example, a registration mark.

- Superimposition of a synchronous operation

One synchronous operation can be superimposed by another synchronous operation.

- Engage/disengage:

Slave axes can be stopped for one cycle or moved for only one cycle, for example, to eject a defective part. The programmable gearing functionality ensures flexibility during engage/disengage functions.

- Synchronize/desynchronize while master axis is in motion:

Slave axes can be synchronized/desynchronized while the master axis is in motion. The user can specify the angular position of the master axis.

- Distributed synchronous operation and therefore the possibility of implementing synchronous operation beyond device boundaries.

Further information:

-

For technical specifications, see Section "Function Overview"

-

For ordering data, see "Runtime Software/General"

Cam

The Cam technology package requires a license and provides the following functions, in addition to the functions provided by the Position and Gear packages:

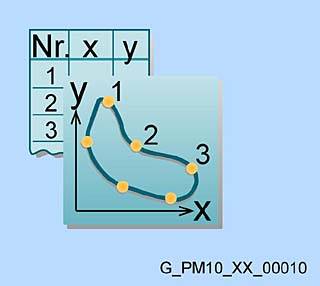

- Cam Functions:

- Definition by means of interpolation points or polynomials

- Polynomials up to the 6th degree with trigonometric component

- Implementation of principles of motion in accordance with VDI 2143

- Transition between interpolation points:

polynomial, linear, and continuous

- Scaling and switching of cam functions, even during motion:

Cam functions can be scaled to master and slave position during operation.

Defined switching of the active cam function is possible during operation.

- Superimposition of 2 synchronous cam operations

Cams can be created and modified using the SCOUT engineering system or an application program.

Temperature control – TControl

The controller core of the Temperature technology package has a DPID structure. Heating and cooling controllers can be configured and parameterized solely for heating or cooling but also as combined heating/cooling controllers.

The functionality of the TControl technology package is supplemented by the application project (APTC). The application project has functional interfaces with the application and data interfaces with the HMI section; it forms part of the SIMOTION Function Library.

The TControl technology package is under license. Various freely selectable functions are available for each temperature channel (the supplementary functions of the AP are marked):

- Each temperature channel can be configured solely for heating or cooling but also as combined heating/cooling loop

- The controllers integrate either a PID or DPID control algorithm, or optionally a control zone functionality.

- In manual output mode, a default manipulated variable can be output.

- The operating mode can be selected for each individual controller channel. For instance, a fixed manipulated variable can be selected as output mode.

The following operating modes are available:

- Adjust to operating setpoint

- Adjust to reduced setpoint (AP)

- Actual value acquisition and output of manual manipulated variable

- Actual value acquisition and 0 output

- Self-tuning

- Actual value acquisition and output of mean manipulated variable (AP) (substitute manipulated variable in case of fault)

- Actual value acquisition and processing

- Gradient check for each new actual value and correction of the respective filter function

- Filter (PT1 element)

- Setpoint input and processing

- Switching between two setpoints via commands (AP)

- Setpoint looping with ramp function (AP)

- Processing and output of output signal

- Digital, pulse-length modulated output signal

- Avoidance of minimum pulse length in input/output cycles with integration of lost pulses

- Manual output value (in manual output mode)

- Manipulated variable limitation

- Substitute manipulated variable (dynamic calculation)

- Self-tuning for heating controller

- This ensures overshoot-free, fast startup and maintaining of the setpoint without any persisting control deviation

- Self tuning can be activated synchronously for specific channels to ensure optimum parameter setting even in extremely coupled temperature loops.

- Hot runner controller

- Startup characteristic (AP)

- Monitoring and alarm functions

- Actual value monitoring by defining tolerance ranges. Inner and outer tolerance range can be specified in absolute values or relative to one another.

- Measuring range monitors for increased operational safety of the plant

- Plausibility check

- Alarm functions

- Weekly timer switch (AP)

Further information:

-

For technical specifications, see Section "Function overview"

-

For ordering data, see "Runtime Software/General"

|