ФункцииMode of operation, ULTRAMAT channel

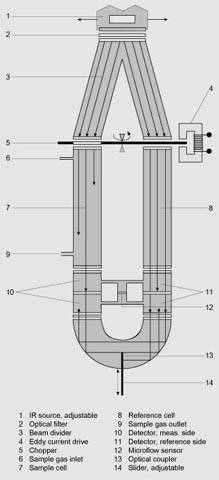

The ULTRAMAT channel operates according to the infrared two-beam alternating light principle with double-layer detector and optical coupler.

The measuring principle is based on the molecule-specific absorption of bands of infrared radiation. The absorbed wavelengths are characteristic to the individual gases, but may partially overlap. This results in cross-sensitivities which are reduced to a minimum in the ULTRAMAT 6 gas analyzers by the following measures:

- Gas-filled filter cell (beam divider)

- Double-layer detector with optical coupler

- Optical filters if necessary.

The figure shows the measuring principle. An IR source (1) which is heated to approx. 700 ºC and which can be shifted to balance the system is divided by the beam divider (3) into two equal beams (sample and reference beams). The beam divider also acts as a filter cell.

The reference beam passes through a reference cell (8) filled with N2 (a non-infrared-active gas) and reaches the right-hand side of the detector (11) practically unattenuated. The sample beam passes through the sample cell (7) through which the sample gas flows and reaches the left-hand side of the detector (10) attenuated to a lesser or greater extent depending on the concentration of the sample gas. The detector is filled with a defined concentration of the gas component to be measured.

The detector is designed as a double-layer detector. The center of the absorption band is preferentially absorbed in the upper detector layer, the edges of the band are absorbed to approximately the same extent in the upper and lower layers. The upper and lower detector layers are connected together via the microflow sensor (12). This coupling means that the spectral sensitivity has a very narrow band.

The optical coupler (13) lengthens the lower receiver cell layer optically. The infrared absorption in the second detector layer is varied by changing the slider position (14). It is thus possible to individually minimize the influence of interfering components.

A chopper (5) rotates between the beam divider and the sample cell and interrupts the two beams alternately and periodically. If absorption takes place in the sample cell, a pulsating flow is generated between the two detector levels which is converted by the microflow sensor (12) into an electric signal.

The microflow sensor consists of two nickel grids heated to approx. 120 °C which, together with two further resistors, form a Wheatstone bridge. The pulsating flow together with the very close arrangement of the Ni grids leads to a change in resistance. This leads to an offset in the bridge which is dependent on the concentration of the sample gas.

Notes

The sample gases have to enter the analyzer dustfree. Avoid condensate in the sample cells. Therefore an appropriate gas preparation is required for most applications.

The ambient air of the analyzer should be, in a large extent, free of high concentration of the component to be measured.

Flow-type reference sides with reduced flow must not be operated with flammable or toxic gases.

Channels with electronically suppressed zero only differ from the standard version in the measuring range parameterizing.

Physically suppressed zeros are carried out as special application.

ULTRAMAT 6, mode of operation

Mode of operation, OXYMAT channel

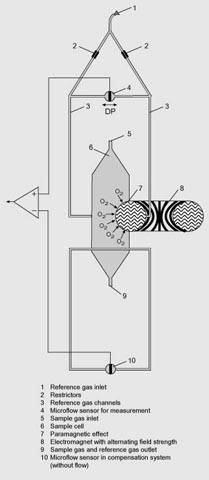

In contrast to almost all other gases, oxygen is paramagnetic. This property is utilized as the measuring principle by the OXYMAT channel.

Oxygen molecules in an inhomogeneous magnetic field are drawn in the direction of increased field strength due to their paramagnetism. When two gases with different oxygen concentrations meet in a magnetic field, a pressure difference is produced between them.

One gas (1) is a reference gas (N2, O2 or air), the other is the sample gas (5). The reference gas is introduced into the sample cell (6) through two channels (3). One of these reference gas streams meets the sample gas within the area of a magnetic field (7). Because the two channels are connected, the pressure, which is proportional to the oxygen concentration, causes a cross flow. This flow is converted into an electric signal by a microflow sensor (4).

The microflow sensor consists of two nickel grids heated to approx. 120 ºC which form a Wheatstone bridge together with two supplementary resistors. The pulsating flow results in a change in the resistance of the Ni grids. This results in a bridge offset which depends on the oxygen concentration in the sample gas.

Because the microflow sensor is located in the reference gas stream, the measurement is not influenced by the thermal conductivity, the specific heat or the internal friction of the sample gas. This also provides a high degree of corrosion resistance because the flow sensor is not exposed to the direct influence of the sample gas.

By using a magnetic field with alternating strength (8), the effect of the background flow in the microflow sensor is not detected, and the measurement is thus independent of the instrument orientation.

The sample cell is directly in the sample path and has a small volume. The microflow sensor thus responds quickly, resulting in a very short response time.

Vibrations frequently occur at the place of measurement and may falsify the measured signal (noise). A further microflow sensor (10) through which no gas passes acts as a vibration sensor. Its signal is applied to the measured signal as compensation.

If the density of the sample gas deviates by more than 50% from that of the reference gas, the compensation microflow sensor (10) is flushed with reference gas just like the measuring sensor (4).

Note

The sample gas needs to be free of dust. Condensate in the cells must be avoided. That is why the most measuring tasks require an appropriate gas preparation.

OXYMAT 6, mode of operation

Essential characteristics

- Four freely-parameterizable measuring ranges per component

- Measuring ranges with physical zero offset possible

- Measuring range identification

- Electrically isolated signal output selectable as 0/2/4 to 20 mA per component

- Autoranging or manual range switching possible; remote switching is also possible

- Storage of measured values possible during adjustments

- Time constants selectable within wide limits (static/dynamic noise suppression); i.e. the response time of the analyzer can be matched to the respective application

- Short response time

- Low long-term drift

- Measuring-point selection for up to 6 measuring points (programmable)

- Measuring point identification

- Monitoring of sample gas flow (option)

- Two-stage access code with authorization code to prevent unintentional and unauthorized inputs

- Automatic range calibration can be parameterized

- Simple handling using menu-based operation with numerical membrane keyboard

- Operation based on NAMUR Recommendation

- Customer-specific analyzer options such as e.g.:

- Customer acceptance

- Tag labels

- Drift recording.

ULTRAMAT channel

- Differential measuring ranges with flow-type reference cell

- Internal pressure sensor for correction of variations in atmospheric pressure in the range 600 to 1200 hPa absolute

- External pressure sensor - only with piping gas path - can be connected for correction of variations in the process gas pressure in the range 600 to 1500 hPa absolute (option)

- Sample cells for use in presence of highly corrosive sample gases (e.g. tantalum layer or Hastelloy C22).

OXYMAT channel

- Monitoring of sample gas and/or reference gas (option)

- Different smallest spans (0.5%, 2.0% or 5.0% O2)

- Analyzer section with flow-type compensation circuit (option): a flow is passed through the compensation branch to reduce the vibration dependency in the case of highly different densities of the sample and reference gases

- Internal pressure sensor for correction of pressure variations in sample gas (range 500 to 2000 hPa absolute)

- External pressure sensor can be connected for correction of variations in sample gas pressure up to 3000 hPa absolute (option), only with piping as the gas path

- Monitoring of reference gas with reference gas connection 3000 to 4000 hPa (option)

- Sample cell for use in presence of highly corrosive sample gases..

Reference gases

|

Measuring range

|

Recommended reference gas

|

Reference gas connection pressure

|

Remarks

|

|

0 to . . . % v/v O2

|

N2

|

2000 to 4000 hPa above sample gas pressure (max. 5000 hPa absolute)

|

The reference gas flow is set automatically to 5 to 10 ml/min (up to 20 ml/min when also flowing through compensation branch)

|

|

. . . to 100% v/v O2 (suppressed zero with full-scale value 100% v/v O2)

|

O2

|

|

Around 21% v/v O2 (suppressed zero with 21% v/v O2 within the span)

|

Air

|

100 hPa with respect to sample gas pressure which may vary by max. 50 hPa around the atmospheric pressure

|

|

Table 1 Reference gases for OXYMAT 6 channel

Correction of zero error / Cross interferences (OXYMAT channel)

|

Residual gas

(concentration 100% v/v)

|

Zero deviation

in % v/v O2absolute

|

Residual gas

(concentration 100% v/v)

|

Zero deviation

in % v/v O2 absolute

|

|

Organic gases

|

|

Inert gases

|

|

|

Acetic acid CH3COOH

|

-0.64

|

Argon Ar

|

-0.25

|

|

Acetylene C2H2

|

-0.29

|

Helium He

|

+0.33

|

|

1,2 butadiene C4H6

|

-0.65

|

Krypton Kr

|

-0.55

|

|

1,3 butadiene C4H6

|

-0.49

|

Neon Ne

|

+0.17

|

|

iso-butane C4H10

|

-1.30

|

Xenon Xe

|

-1.05

|

|

n-butane C4H10

|

-1.26

|

|

|

1-butene C4H6

|

-0.96

|

Anorganic gases

|

|

|

iso-butene C4H8

|

-1.06

|

Ammonia NH3

|

-0.20

|

|

Cyclo-hexane C6H12

|

-1.84

|

Carbon dioxide CO2

|

-0.30

|

|

Dichlorodifluoromethane (R12) CCl2F2

|

-1.32

|

Carbon monoxide CO

|

+0.07

|

|

Ethane C2H6

|

-0.49

|

Chlorine Cl2

|

-0.94

|

|

Ethylene C2H4

|

-0.22

|

Dinitrogen monoxide N2O

|

-0.23

|

|

n-heptane C7H16

|

-2.4

|

Hydrogen H2

|

+0.26

|

|

n-hexane C6H14

|

-2.02

|

Hydrogen bromide HBr

|

-0.76

|

|

Methane CH4

|

-0.18

|

Hydrogen chloride HCl

|

-0.35

|

|

Methanol CH3OH

|

-0.31

|

Hydrogen fluoride HF

|

-0.10

|

|

n-octane C8H18

|

-2.78

|

Hydrogen iodide HI

|

-1.19

|

|

n-pentane C5H12

|

-1.68

|

Hydrogen sulphide H2S

|

-0.44

|

|

iso-pentane C5H12

|

-1.49

|

Oxygen O2

|

+100

|

|

Propane C3H8

|

-0.87

|

Nitrogen N2

|

0.00

|

|

Propylene C3H6

|

-0.64

|

Nitrogen dioxide NO2

|

+20.00

|

|

Trichlorofluoromethane (R11) CCl3F

|

-1.63

|

Nitrogen oxide NO

|

+42.94

|

|

Vinyl chloride C2H3Cl

|

-0.77

|

Sulphur dioxide SO2

|

-0.20

|

|

Vinyl fluoride C2H3F

|

-0.55

|

Sulphur hexafluoride SF6

|

-1.05

|

|

1,1 vinylidene chloride C2H2Cl2

|

-1.22

|

Water H2O

|

-0.03

|

Table 2 Zero error due to diamagnetism or paramagnetism of residual gases with nitrogen as the reference gas at 60 °C and 1000 hPa absolute (according to IEC 1207/3)

Conversion to other temperatures:

The zero errors mentionned in Table 2 must be multiplied with a correction factor (k):

- with diamagnetic gases: k = 333 K / (ϑ [°C] + 273 K)

- with paramagnetic gases: k = [333 K / (ϑ [°C] + 273 K)]2

(all diamagnetic gases have a negative zero error).

|