|

|

19"" - корпус - ULTRAMAT/OXYMAT 6 |

Технические данные

|

General

|

|

Position of use

|

Front panel vertical

|

|

Conformity

|

CE identification EN 50081-1 and EN 50082-2

|

|

Design, enclosure

|

|

Weight

|

Approx. 21 kg

|

|

Degree of protection

|

IP20 according to EN 60529

|

|

Electrical characteristics

|

|

EMC interference immunity

(ElectroMagnetic Compatibility)

|

According to standard requirements of NAMUR NE21 (08/98)

|

|

Electrical safety

|

According to EN 61010-1, overvoltage category III

|

|

Power supply

|

100 … 120 V AC (rated range 90 V … 132 V), 48 … 63 Hz or 200 … 240 V AC (rated range 180 V … 264 V), 48 … 63 Hz

|

|

Power consumption

|

approx. 70 VA

|

|

Fuses

|

120 ... 120 V: F1/F2 = T 1.6 A;

200 ... 240 V: F1/F2 = T 1 A

|

|

Electrical inputs and outputs (per channel)

|

|

Analog output

|

0/2/4 … 20 mA, floating, max. load 750 Ώ

|

|

Relay outputs

|

6, with changeover contacts, freely selectable, e.g. for range identification;

loading capacity: 24 V AC/DC/1 A, floating, non sparking

|

|

Analog inputs

|

2, designed for 0/2/4 … 20 mA, for external pressure sensor and correction of influence of residual gas (correction of cross interference)

|

|

Binary inputs

|

6, designed for 24 V, floating, freely selectable, e.g. for range switching

|

|

Serial interface

|

RS 485

|

|

Options

|

Autocal function with 8 additional binary inputs and 8 relay outputs; also with PROFIBUS PA and PROFIBUS DP

|

|

Ambient conditions

|

|

Perm. ambient temperature

|

-30 … +70 °C during storage and transport,

+5 … +45 ºC during operation

|

|

Permissible humidity

|

< 90% relative humidity, during storage and transport (dew point must not be fallen below)

|

|

Technical data, ULTRAMAT channel

|

|

|

Measuring ranges

|

4, switchable internally and externally; autoranging is also possible

|

|

Smallest possible measuring range

|

Depending on application, e.g.:

CO: 0 … 10 vpm

CO2: 0 … 5 vpm

|

|

Largest possible measuring range

|

Depending on application

|

|

Measuring ranges with suppressed zero

|

Any zero point is possible between 0 and 100%; smallest possible span 20%

|

|

Characteristic

|

Linearized

|

|

Gas inlet conditions

|

|

Permissible sample gas pressure

|

|

|

|

600 … 1500 hPa (absolute)

|

|

|

600 … 1300 hPa (absolute)

|

|

Sample gas flow

|

18 … 90 l/h (0.3 … 1.5 l/min)

|

|

Sample gas temperature

|

0 … 50 ºC

|

|

Sample gas humidity

|

< 90 % relative humidity or depending on application, without condensation

|

|

Time response

|

|

Warm-up period

|

With amb. temperature < 30 min (maximum accuracy achieved after 2 hours)

|

|

Response time (T90 time)

|

Dependent on length of analyzer cell, sample gas line and parameterizable damping

|

|

Damping (electric time constant)

|

0 to 100 s, programmable

|

|

Dead time (purging time of gas path in analyzer at 1 l/min)

|

Approx. 0.5 to 5 s, depending on version

|

|

Time for internal signal processing

|

< 1 s

|

|

Pressure correction range

|

|

Pressure sensor

|

|

|

|

600 … 1200 hPa absolute

|

|

|

600 … 1500 hPa absolute

|

|

Measuring response (referred to 1000 hPa absolute sample gas pressure, 0.5 l/min sample gas flow and 25 °C ambient temperature)

|

|

Output signal fluctuation

|

± 0,1% ... ± 1% of smallest possible measuring range specified on rating plate depending on the unit electronic time constant (corresponds to ± 0.33% with 2σ)

|

|

Zero drift

|

< 1% of measuring range/week

|

|

Measured-value drift

|

< 1% of measuring range/week

|

|

Repeatability

|

≤ 1% of respective measuring range

|

|

Linearity error

|

< 0.5% of full-scale value

|

|

Influencing variables (referred to 1000 hPa absolute sample gas pressure, 0.5 l/min sample gas flow and 25 °C ambient temperature)

|

|

Ambient temperature

|

< 1% of measuring range/10 K (only with stable EK temperature)

|

|

Sample gas pressure

|

With pressure compensation: < 0.15% of span/1% change in atmospheric pressure

without pressure compensation: < 1.5% of span/1% change in atmospheric pressure

|

|

Sample gas flow

|

Negligible

|

|

Power supply

|

< 0.1% of output signal span with rated voltage ± 10%

|

|

Ambient conditions

|

Application-dependent influencing of measurement if ambient air contains measured component or cross-sensitive gases

|

|

Technical data, OXYMAT channel

|

|

Measuring ranges

|

4, switchable internally and externally; autoranging is also possible

|

|

Smallest possible measuring span(referred to 1000 hPa absolute sample gas pressure, 0.5 l/min sample gas flow and 25 °C ambient temperature)

|

0.5% v/v, 2% v/v or 5% v/v O2

|

|

Largest possible measuring span

|

100 % v/v O2

|

|

Measuring ranges with suppressed zero

|

Any zero point is possible between 0 and 100% v/v as long as a suitable reference gas is used

|

|

Gas inlet conditions

|

|

|

Permissible sample gas pressure

|

|

|

|

500 … 3000 hPa absolute

|

|

|

|

|

|

500 … 1500 hPa absolute

|

|

|

500 … 1300 hPa absolute

|

|

Sample gas flow

|

18 … 60 l/h (0.3 … 1 l/min)

|

|

Sample gas temperature

|

0 … 50 ºC

|

|

Sample gas humidity

|

< 90% RH (relative humidity)

|

|

Time response

|

|

Warm-up period

|

With ambient temperature < 30 min (maximum accuracy achieved after 2 hours)

|

|

Reading delay time

|

min. 1.5 … 3.5 s, depending on version

|

|

Damping (electric time constant)

|

0 to 100 s, programmable

|

|

Dead time (purging time of gas path in analyzer at 1 l/min)

|

Approx. 0.5 … 2.5 s depending on version

|

|

Time for internal signal processing

|

< 1 s

|

|

Pressure correction range

|

|

Pressure sensor

|

|

|

|

500 … 2000 hPa absolute

|

|

|

500 … 3000 hPa absolute

|

|

Measuring response

(referred to 1000 hPa absolute sample gas pressure, 0.5 l/min sample gas flow and 25 °C ambient temperature)

|

|

Output signal fluctuation

|

< 0.75% of smallest possible measuring range specified on rating plate with an electronic time constant of 1 s (corresponds to ± 0.25% with 2σ)

|

|

Zero drift

|

< 0.5%/month of smallest possible meas. span specified on rating plate

|

|

Measured-value drift

|

< 0.5%/month of respective measuring span

|

|

Repeatability

|

< 1%/month of respective measuring span

|

|

Linearity error

|

< 1%/month of respective measuring span

|

|

Influencing variables (referred to 1000 hPa absolute sample gas pressure, 0.5 l/min sample gas flow and 25 °C ambient temperature)

|

|

Ambient temperature

|

< 0.5%/10 K referred to the smallest possible measuring span according to rating plate with span 0.5%: 1%/10 K

|

|

Sample gas pressure (with air (100 hPa) as reference gas, a correction of the atmospheric pressure fluctuations is only possible when the sample gas is vented to ambient air)

|

Without pressure compensation: < 2% of measuring span/1% change in pressure;

with pressure compensation: < 0.2% of measuring span/1% change in pressure

|

|

Residual gases

|

Deviation in zero point corresponding to paramagnetic or diamagnetic deviation of residual gas

|

|

Sample gas flow

|

< 1% of smallest possible measuring span according to rating plate with a change in flow of 0.1 l/min within the permissible flow range

|

|

Power supply

|

< 0.1% of output signal span with rated voltage ± 10%

|

|

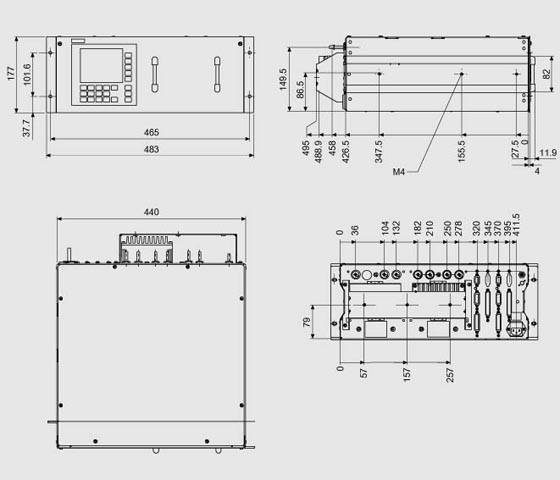

Чертеж

ULTRAMAT/OXYMAT 6, 19“ unit, dimensions in mm |

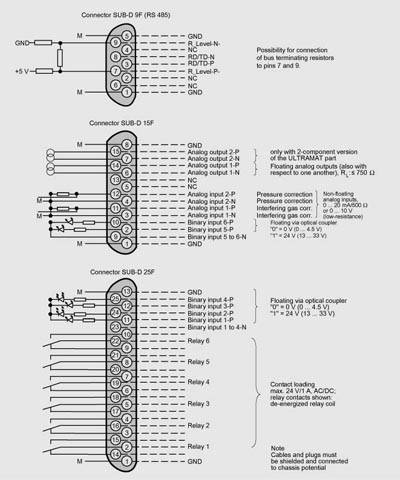

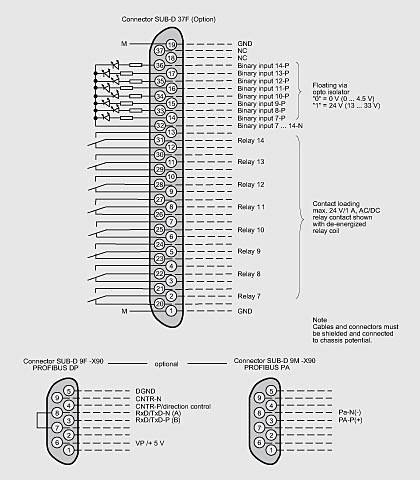

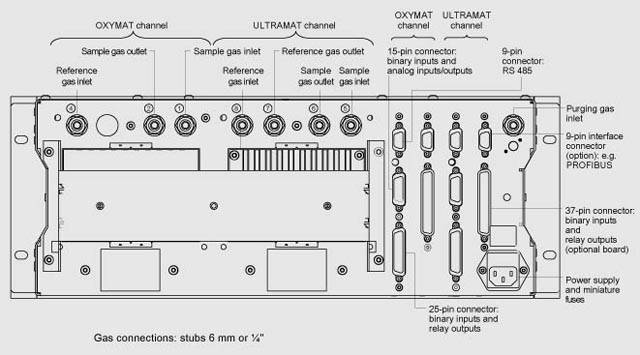

Схема подключенияPin assignment (electrical and gas connections)

ULTRAMAT/OXYMAT 6, 19“ unit, pin assignment

ULTRAMAT/OXYMAT 6, 19“ unit, pin assignment of Autocal board and PROFIBUS connectors

ULTRAMAT/OXYMAT 6, 19“ unit, gas and electrical connections

|

Заказные данные

| Заказной № | Описание | Вес (кг) | Доставка | Мин. зак. (шт) |

| 7MB2023-.....-.... | АНАЛИЗАТОР ULTRAMAT/OXYMAT 6 ИСПОЛНЕНИЕ 19" ДЛЯ МОНТАЖА В ШКАФ | 21 | по запросу (D) | 1 |

| 7MB2024-.....-.... | АНАЛИЗАТОР ULTRAMAT 6 ДЛЯ ИЗМЕРЕНИЯ О2 И IR АКТИВНОГО ГАЗА | 21 | по запросу (D) | 1 |

|

Аксессуары

| Заказной № | Описание | Вес (кг) | Доставка | Мин. зак. (шт) |

| A5E00057307 | AUTOCAL BOARD WITH 8 BINARY- INPUTS/OUTPUTS AND PROFIBUS PA | 0.5 | по запросу (D) | 1 |

| A5E00057312 | AUTOCAL BOARD WITH MIT 8 BINARY INPUTS AND 8 BINARY OUTPUTS AND PROFIBUS DP | 0.5 | по запросу (D) | 1 |

| C79000-G5200-C143 | РУКОВОДСТВО ULTRAMAT 6 / OXYMAT 6 | 0.42 | 4 - 6 недель (B) | 1 |

| C79000-G5272-C143 | РУКОВОДСТВО (ITALIAN) ULTRAMAT 6 / OXYMAT 6 | 0.42 | 4 - 6 недель (B) | 1 |

| C79000-G5276-C143 | РУКОВОДСТВО (ENGLISH) ULTRAMAT 6 / OXYMAT 6 | 0.8 | 4 - 6 недель (B) | 1 |

| C79000-G5277-C143 | РУКОВОДСТВО (FRENCH) ULTRAMAT6 / OXYMAT6 | 0.335 | 4 - 6 недель (B) | 1 |

| C79000-G5278-C143 | РУКОВОДСТВО (SPANISH) ULTRAMAT6 / OXYMAT6 | 0.41 | 4 - 6 недель (B) | 1 |

| C79451-A3364-D61 | ELAN GATEWAY SIPROM GA UP-DATE COMMUNICATION BY TCP/IP AND ETHERNET | 0.5 | 4 - 6 недель (B) | 1 |

| C79451-A3480-D33 | RETROFIT KIT SERIAL INTERFACE FOR AUTOMOTIV (AK)FOR ULTRAMAT 6E 2P AND ULTRAMAT/OXYMAT 6E | 0.25 | по запросу (D) | 1 |

| C79451-Z1589-U1 | INTERFACE CONVERTER RS 485 / RS 232 (RETROFIT SET) | 1 | 6 - 8 недель (C) | 1 |

| |

|

|