|

|

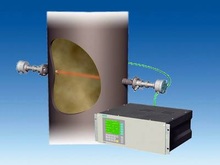

LDS 6 is a diode laser based gas sensor with a measuring principle based on the specific light absorption of different gas components. LDS 6 is suitable for fast and non-intrusive measurements of gas concentrations or temperatures in process or flue gases. One or two signals of up to three measuring points are processed simultaneously with one central analyser unit. The cross duct in-situ sensors at each measuring point can be separated up to 1 kilometer from the central unit by using fiber optic cables. The sensors are designed for operation under harsh environmental conditions and contain a minimum of electrical components. By connecting a bypass stream to a separate flow cell measurements can also be carried out extractively instead of in-situ.

LDS 6, typical installation with cross duct sensors |

ОсобенностиThe in-situ gas analyzer LDS 6 is characterized by a high operational availability, unique analytic selectivity and by a broad scope of suitable applications. LDS 6 enables the measurement of one or two gas components or - if desired - the gas temperature directly in the process

- At the presence of up to 100 vol.% steam

- At high levels of dust load (up to 100 g/Nm3)

- In hot, corrosive, explosive, or toxic gases

- In applications showing strong varying gas compositions

- Under harsh environmental conditions at the measuring point

- Highly selective, i.e. mostly without cross interferences.

LDS 6 allows:

- Little installation efforts

- Minimum maintenance requirements

- High ruggedness and long-term stability

- Real-time measurements.

Moreover, the instrument provides warning and failure messages at:

- Need for maintenance

- Erroneous self calibration

- Bad signal quality

- Exceeding a lower or upper alarm level for the measurement variable

- Transmission exceeding upper or lower limit.

|

Область примененияApplication areas

- Process optimisation

- Continuous emission monitoring for all kinds of fuels (oil, gas, coal, and others)

- Process measurements in power utilities and any kind of incinerator

- Process control

- Explosion protection

- Measurements in corrosive and toxic gases

- Quality control

- Environmental protection

- Plant and job safety.

Branches

- Power plants

- Waste incinerators

- Cement industry

- Chemical and petrochemical plants

- Automotive industry

- Glass and ceramics production

- Research and development.

Special applications

In addition to the standard combinations special applications are available upon request. |

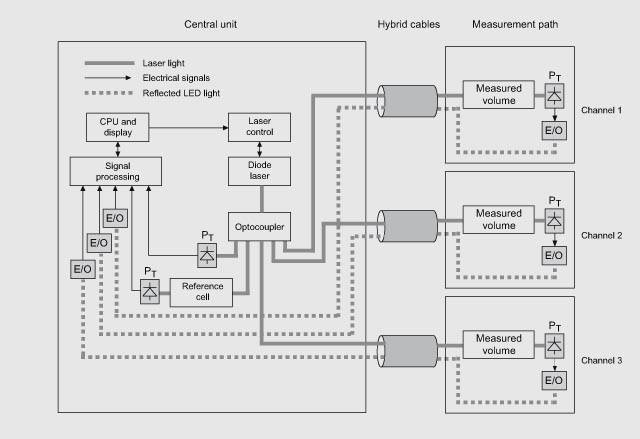

ДизайнLDS 6 consists of a central unit, accomplished by up to three pairs of cross duct sensors in a transmitter/receiver configuration. The connection between the central unit and the sensors is established by a so-called hybrid cable, which contains optical fibers and copper wires. An additional loop cable connects both sensor parts.

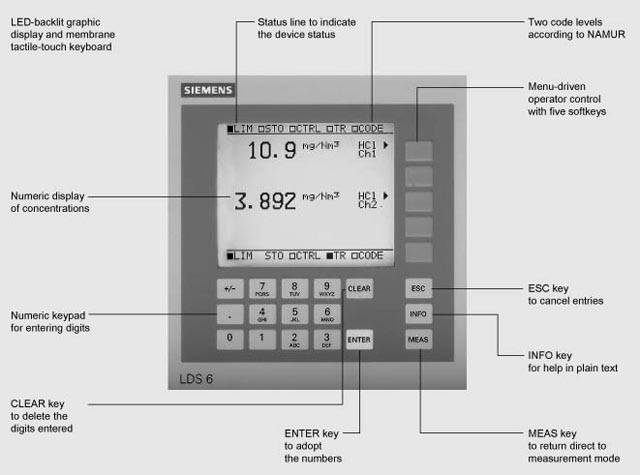

Central unit

The central unit is housed in a 19"-rack with 4 holders for assembly

- in a swing gate

- in racks with or without telescope rails.

Display and control panel

- Large LCD field for simultaneous display of measurement result and device status

- Contrast of the LCD field is adjustable via the menu

- LED illumination of the display

- Cleanable foil touch pad with soft-keys

- Menu-controlled operation for parameterization and diagnoses

- Operation help given in plain text.

Input and output connections

- One to three measurement channels with hybrid connections for the sensors at the measuring points

- Per channel 2 analog inputs for process gas temperature and pressure

- Per channel 2 analog outputs for gas concentration(s) or gas temperature and concentration, respectively

- Per channel 6 freely configurable binary inputs for signalling of fault or maintenance request from external temperature or pressure transducers or purging failure.

- Per channel 6 freely configurable binary outputs (signalling of fault, maintenance request, function control, transmission limit alarm, concentration limit alarm, store analog output).

Communication

Network connection: Ethernet (T-Base-10) for remote diagnosis and maintenance.

LDS 6 central unit, membrane keyboard and graphic display

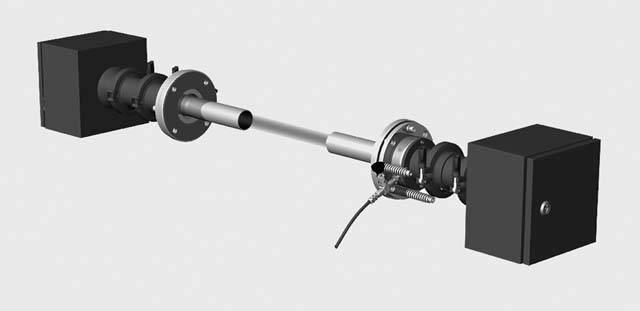

Transmission sensors

Sensor CD 6 of the LDS 6 (non-EEx), transmitter or receiver unit

Sensor pair CD 3002 of the LDS 6 (EEx), transmitter and receiver unit

- In-situ cross duct sensors, configured as transmitter and receiver unit, connected via loop cable

- Sensor pair CD 6 for non-EEx environments, sensor pair CD 3002 for EEx environments

- Stainless steel, partially painted

- Protection class IP67 (non-EEx) sensor and IP65 (EEx)

- Adjustable window flanges with flange connection DN65/PN6, optional: ANSI 4“/150 lbs

- Purging facilities on the process and the sensor side, configurable application with purging gas connections for:

- Instrument air

- Air blower fan

- Steam

- Nitrogen

- Any other suitable purging media

- Fast connectors for cleaning the measurement openings and the sensor window

- Optional Ex-protected version according to ATEX II 1GD EEx ia IIC T4.

Parts in contact with the process gases

The sensors normally do not come into contact with the process gas, since purging is applied at the process side. The material used for the tubes defining the purge volume in front of the sensor windows is selected according to the process conditions. Available tube materials are stainless steel (standard), Hastelloy, plastics (PP) and ceramics.

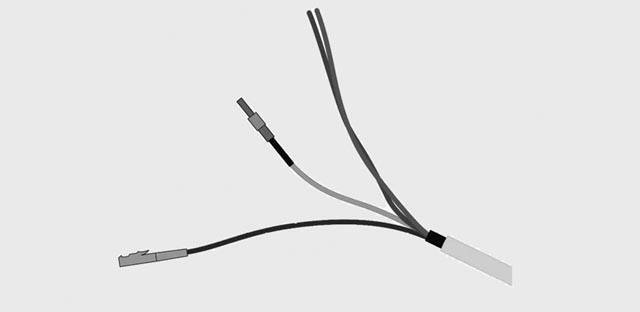

Hybrid and loop cable

Combination of fiber optic cables and twisted copper wires to connect the sensors to the central unit. The hybrid cable connects the central unit with the transmitter unit of the sensor, the loop cable connects the transmitter and the receiver unit of the sensor.

- Max. 1000 m distance between central unit and measuring point

- Hybrid and loop cable:

- Multimode fiber-optic cable, provided with SMA connections for transmission of the measurement signal

- Two-core copper cable, in twisted pair configuration, for +24 V supply of the receiver electronics

- Additionally for the hybrid cable:

- Monomode fiber optic cable, configured double-sided with angle-polished E2000 connectors for the transmission of laser light

- Robust cable coating for mounting in open cable ducts or ductworks

- Oil-resistant polyurethane as jacket material.

Connections of the hybrid cable |

Функции

Working principle

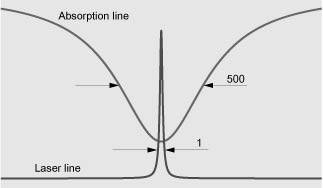

LDS 6 is a gas analyzer employing single-line molecular absorption spectroscopy. A diode laser emits a beam of near-infrared light, which is sent through the process gas and detected by a receiver unit. The wavelength of the laser diode output is tuned to a gas specific absorption line. The laser is scanning continuously over this single absorption line with very high spectral resolution. The result is a fully resolved single molecular line which is analysed in terms of absorption strengths and line shape. The measurement is free of cross-interferences, since the quasi-monochromatic laser light is absorbed very selectively by only one specific molecular line in the scanned spectral range.

Basic design of the LDS 6

LDS 6 is connected to a measuring point by fiber optics. The laser light is guided by a single mode fibre from the central unit to the transmitter unit of the in-situ sensor. The sensor consists of a transmitter and a receiver; their distance defines the measurement path. In the receiver box, the light is focused onto a suitable detector. The detector signal is then transferred into an optical signal and is transmitted via a second optical fibre to the central unit, where the concentration of the gas component is determined from the detected absorption signal.

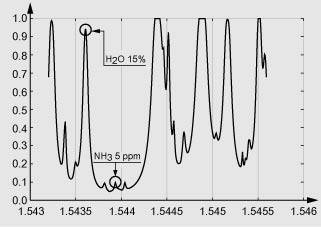

LDS 6 measures normally a single gas component. In some specific cases two components can be measured simultaneously, if their absorption lines are so close to each other that they can be detected within one laser scan (for example like water(H2O) and ammonia (NH3) in the spectrum shown.

Absorption spectra of water and ammonia

Moreover, in some applications it is possible to determine the gas temperature as a measurement value. In this case, the ratio of the absorbance of two characteristic lines of the same molecule measured at the same time in the same volume gives the actual temperature in the process gas.

Typical measurable gases for LDS 6 are:

- Oxygen / O2

- Hydro fluorine / HF

- Hydro chlorine / HCl

- Ammonia / NH3

- Water vapour / H2O

- Carbon monoxide / CO

- Carbon dioxide / CO2.

By using an internal reference cell normally filled with the gas measured, the stability of the spectrometer is permanently checked in a reference channel.

By doing so, the continuous calibration of the instrument is guaranteed without the need of carrying out external re-calibrations by bottled test gases or reference cuvettes.

Typical spectral width of an absorption line compared to the width of the laser emission

Influences on the measurement

-

Dust load: As long as the laser beam is able to give a suitable detector signal, the dust load of the process gases does not influence the analytical result. By applying a dynamic background correction, measurements can be carried out without any negative impact. Typical particle densities from below 1 mg/Nm3 to 100 g/Nm3 can be handled by the LDS 6. The varying dust loads are compensated by scanning the laser over the gas absorption line and the inherent background. At a scan position next to the absorption line, the instrument can "see" only absorption caused by the dust load where at the line center the signal is composed of the molecular absorption and the continuous, unspecific background absorption. While using a wavelength modulation technique, the actual measured transmission is always compared with the baseline. In the signal processing, a lock-in detection scheme delivers a signal only from the molecular line free of background.

Dust load and path length are competing: the higher the dust load in the process, the shorter the max. path length possible.

-

Temperature: The temperature influence on the absorption line strength is compensated by a correction factor determined during calibration. A temperature signal can be fed into the instrument from an external temperature sensor. The signal is then used for a mathematical correction of the influence of the temperature on the observed line strength.

At high temperatures where thermal radiation of the gas and the dust is present or flames can occur in the measurement path, the detector is shielded with an optical band pass filter in front in order not to saturate it with the strong background radiation.

-

Pressure: The gas pressure can affect the line shape of the molecular absorption line. LDS 6 uses a curve fitting algorithm to adapt to the resulting line shape. Additionally, an external pressure signal can be fed to the instrument to give a complete mathematical compensation for the pressure influence incl. the density effect.

-

Cross interferences: Since LDS 6 derives its signal from a single fully resolved molecular absorption, cross interferences with other gases are quite unlikely. LDS 6 is therefore able to measure the desired gas components very selectively. In special cases, the composition of the process gas might have an influence on the shape of the absorption line features. This influence is compensated by analysing the full shape of the detected signal curve by customized algorithms.

-

Optical path length: The absorption values analyzed by the LDS 6 are typically small. As a result of Beer -Lambert's law, the signal strength of the absorption lines can be approximated as being linear dependent on the optical path length within the gas. Therefore, the precision in determine the effective optical path length in the process might limit the overall precision of the measurement.

As the sensor openings towards the process normally need to be purged to keep them clean over a long period of time, the thickness of the mixing zone between the purging media and the process gas and its concentration distribution need to be considered. In a typical cross duct installation with some meters of path, the influence of the purging gas on the effective path length can be neglected.

Path length and load are competing: the higher the dust load in the process, the shorter the max. path length possible.

Maintenance and failure alarms

LDS 6 delivers warnings by relays:

- Need for maintenance (measurement value is not influenced)

- Operational fault (measurement value can be influenced).

Note

Individual requirements for the measuring point can make the utilization of special sensor equipment necessary. The possibilities for adapting the sensors are:

- Different purging media available like instrument air, ambient air, nitrogen or steam

- Different purging modes on process and sensor side

- Special materials of purging tubes and/or the sensor flanges

- Cooling or heating of the sensors

- EEx-proof sensor configurations

Essential characteristics

- Integrated self-calibration with an internal reference cell

- Negligible long-term drifts of zero and span

- Dynamic background correction for varying dust loads

- Galvanically isolated signal outputs of 4-20 mA (also inverted)

- Easy-to-handle with menu-driven operation

- Selectable time constants (response time)

- Two user levels with individual access codes for prevention of unwanted and unauthorised operations

- Operation conformity with NAMUR recommendations

- Monitoring of overall optical transmission

- Remote preventive maintenance, and service operations accessible via Ethernet

- Straightforward replacement of the central units, since connectors can easily be removed

- Deterioration- and corrosion-free sensor and central unit housing

- Easy operation with a numerical keypad and menu prompt

- Modular design, allows exchange of components in the field.

|

ИнтеграцияCommunication

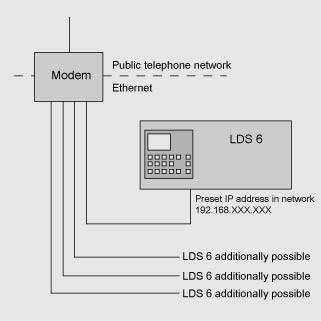

LDS 6 is capable to transmit and receive data via Ethernet connection by using the software LDScom. This installation and service tool is capable to check and adjust remotely instrument status and calibration parameters. If desired, almost a full system check can be done remotely. In case of service, information can be addressed via modem to Siemens service personnel, who take care of appropriate measures remotely.

This remote control capability is established by using a standard LAN modem.

External connection of LDS 6 via modem to establish remote maintenance capabilities | |

|

|